Description

BURN BARRIER™ – 10-10 is a solvent-based intumescent fire retardant paint. It is designed for use on interior surfaces. The most efficient fire protection!

BURN BARRIER™ – 10-10 description

BURN BARRIER™ – 10-10 is a solvent-based intumescent fire retardant paint and is

manufactured in accordance with Federal Specification TT-P-26C. It is designed for use on

interior surfaces. The coating dries quickly to a velvety flat finish, having the appearance of

conventional paint. Upon exposure to fire, BURN BARRIER™ – 10-10 puffs up (intumesces),

forming a dense cellular foam layer. This foam layer greatly reduces the surface

burning characteristics of combustible materials and retards the penetration of heat to

metal surfaces.

Surface Preparation:

Surface preparation should be carried out according to good painting practices. All dirt,

grease, oil, wax, rust and other foreign matter must be removed.

New Surfaces:

New wood, fiberboard and other surfaces having uneven or excessive porosity should be

sealed with No. 3001 Alkyd Primer, and allowed to dry a minimum of 16 hours before

applying BURN BARRIER 10-10. New drywall, plaster and masonry surfaces should be

internally dry and cured. Prime with No. 3003 Acrylic Primer, and allow to dry overnight

before applying BURN BARRIER 10-10. New metal surfaces must be primed. Apply No.

3004 Universal Primer or No. 3005 Two Component Epoxy Primer. Allow to dry 16 hours

or until hard, before applying BURN BARRIER™ 10-10.

Previously Painted Surfaces:

BURN BARRIER™ 10-10 may be applied directly to existing paint that is tightly adherent

and in good condition.All glossy surfaces should be dulled with sandpaper. Spot prime

where necessary with appropriate primers as shown above, before application of BURN

BARRIER™ 10-10.

BURN BARRIER™ 10-10 Application:

BURN BARRIER 10-10 is ready to use. It can be applied by brush, roller, airless or

conventional heavy duty spray equipment. Stir thoroughly and apply, using a full bodied

coat. If thinning is required, use only BURN BARRIER™ 10-10 Reducer. Do not apply in

temperatures below 50°F (100 C).

Suggested Coverage Rate: 190 to 230 sq.ft./US gallon (230 to 275 sq.ft./Imp. gal) in one

or two coats. See fire hazard classification for specific coverage rates.

Drying Time:

Dries to touch in approximately 4 hours. Allow at least 24 hours drying time before over

coating.

Thinners:

For thinning use BURN BARRIER™ 10-10 Reducer, and when cleaning use Rule 66

mineral spirits.

Fire Tests:

Flame Spread Rating: Class “A”. When tested in accordance with ASTM E-84 (NFPA 255) the

coating obtained the following fire hazard classifications. A complete Underwriters’ Laboratory

report is available upon request.

FIRE HAZARD CLASSIFICATION:

| Surface | Douglas Fir | Douglas Fir |

| Flame Spread Rating | 15 | 15 |

| Fuel Contributed | 15 | 15 |

| Smoke Developed | 15 | 15 |

| Number of preliminary coats | None | None |

| Number of Fire Retardant coats | 1 | 1 |

| Rate per coat: | ||

| sq.ft./gal. U.S. (Imp) | 230 (275) | 190 (230) |

| Number of Overcoats | None | *1 |

| sq.ft./gal. U.S. (Imp) | 615 (750) |

*Overcoated with No. 40-40 Low Gloss Fire Retardant Coating.

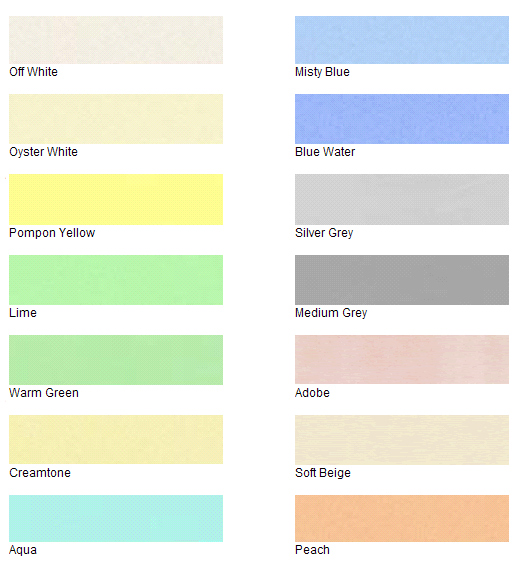

Tinting:

Available in white, off-white, and pastel shades, or may be field tinted with most universal

or oil tinting colorants. Tinting colorants should not exceed 2 fluid ounces per gallon.

Packaging:

Standard packaging, 1 gallon, 5 gallon and 55 gallon containers.

PRECAUTIONS:

CAUTION! COMBUSTIBLE. Keep away from heat and open flame. Avoid prolonged

contact with skin and breathing of vapor or spray mist. Do not take internally. Close

container after each use. Use only with adequate ventilation. KEEP OUT OF REACH OF CHILDREN. Protect from freezing.

NOTE: All porous surfaces should be properly sealed before applying fire retardant paint or

varnish.

BURN BARRIER™ 10-10 security precautions?

CAUTION: It is recommended that a test application be completed prior to end use.

Information provided herein is based on tests believed to be reliable. Inasmuch as Fire

Retardants inc. has no control over the use or application to which others may put this

material, we make no guarantee or warranty. Our products are sold on the condition that each

user of the material make their own evaluation to determine the material’s suitability for their

own particular use.

© Fire Retardants Inc. All Rights Reserved.

Color Options: