Description

Product Description:

BURN BARRIER™ No. 40-40 is a low-gloss general-purpose latex (water base) coating that is fire rated over noncombustible surfaces, and as an overcoat for BURN BARRIER™ intumescent fire retardant paints. It dries quickly to yield a highly cleansable-scrubbable, water resistant film that possesses excellent adhesion flexibility, and toughness. No. 40-40 is suitable for application to all interior surfaces (except floors and shelving). It can also be used on exterior masonry surfaces where a highly water resistant, decorative coating is desired.

Surface Preparation:

Surface preparation should be carried out according to good painting practices. Remove all loose, peeling or powdery paint from the surface. All dirt, grease, oil, wax, and other foreign matter MUST be removed with a detergent. Rinse surfaces thoroughly with clear water and allow to dry. Repair all cracks, holes,and other surface irregularities. Allow to dry, sand lightly and prime repaired surfaces with No. 40-40.

New Surfaces: BURN BARRIER™ No. 40-40 can be applied directly to primed steel and directly to all other noncombustible surfaces. All combustible surfaces such as wood, plywood, fiberboard, etc., must be coated with BURN BARRIER™ intumescent fire retardant paint, before application of BURN BARRIER™ No. 40-40.

Previously Painted Surface: Noncombustible surfaces having excessive conventional paint film buildup, and all combustible surfaces such as wood, plywood, fiberboard, etc., must be coated with BURN BARRIER™ intumescent tire retardant paint, before application of BURN BARRIER™ No. 40-40.

Application:

BURN BARRIER™ No. 40-40 is ready to use. It can be applied by brush, roller, airless or conventional spray equipment. Stir thoroughly and apply, using a full-bodied coat. If thinning is required, use WATER only, do not exceed 1/2 pint per gallon. Do not apply in temperatures below 50F (10C).

Suggested Coverage Rate: 350 to 625 sq.ft./U.S. gallon (8.6 to 15.3 m2/L) depending on substrate. See fire hazard classification for specific coverage rates.

Drying Time: Dries to touch in approximately 30 minutes, can be recoated in I to 2 hours.

Thinning: For thinning, use only water (maximum 1/2 pint per gallon). For equipment clean up use warm soapy water.

Fire Tests: Flame Spread Raring: Class “A”. When tested in accordance with ASTM E-84

(NFPA 255), the coating obtained the following fire hazard classification.

FIRE HAZARD CLASSIFICATION:

| Coating System Details Flame Smoke Spread Developed Primer – None Type 10-10 (base coat) applied in one coat at 190 sq.ft./ U.S. gal. (4.7 m2/L) Type 40-40 top coating applied in one coat at 625 sq ft. U.S. gal. (915.3 m2/L) |

(When Applied to Douglas Fir)

|

| Coating System Details Primer – None Type 40-40 (base coat) applied in one coat at 350 sq.ft./ U.S. gal. (8.6 m2/L) Topcoat – None |

(When Applied to Asbestos-Cement Board)

|

PRECAUTIONS:

CAUTION! Do not take internally. Close container after each use.

KEEP OUT OF REACH OF CHILDREN. Protect from freezing. Information provided herein is based on information available at the time of printing. However, we make no guarantee or warranty that this product meet or complies with any federal, state local or foreign goverment code requirements. As we cannot anticipate all conditions under which this information and our products, or the products of other manufacturers in combination with our products may be used, we accept no responsibility for the results obtained by the application of this information or the safety and suitability of our products, either alone or or in combination for their own purposes. We sell our products without warranty or guarantee, and buyers and users assume all responsibility and liability for loss or damage arising from the use of this information, handling and use of our handling and use of our products whether used alone or in combination withe other products.

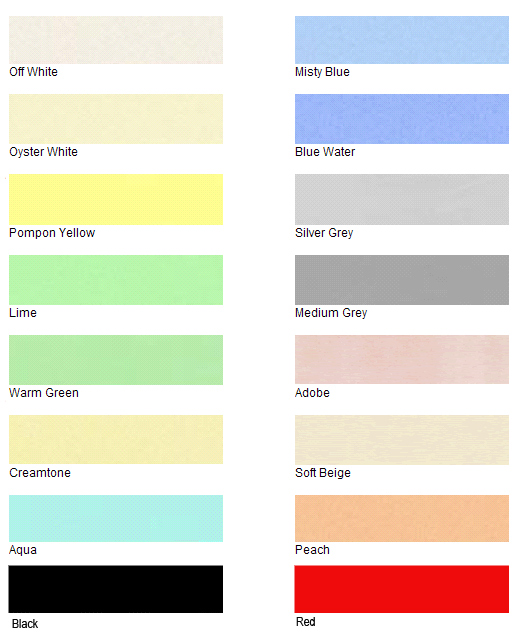

Color Options: